Application

The proposal addressed the FCH-01-4-2019 topic 'Towards a better understanding of charge, mass and heat transports in new generation PEM fuel cells MEA for automotive applications'. The project was funded 2.3 M€ from Fuel Cells and Hydrogen Joint Undertaking and will run from 2020-2022 Under the Grant Agreement number 875155.

State-of-art for MEA components

Several of the consortium partners (JMFC, BMW, PRETEXO, IMTEK) are partners in three current FCH JU funded projects GAIA, INSPIRE and VOLUMETRIQ. These projects have demonstrated power densities of 1.5 W/cm2 in relevant OEM stack hardware. The materials and components developed in these projects will be considered state-of-art for the CAMELOT project. Additionally, TUC and JMFC are involved in the MAMA-MEA project, also funded by FCH JU, focusing on a mass production of MEAs.

The FCH-JU's Multi-Annual Work Plan sets goals for next generation MEAs: Lower noble metal catalyst loadings (< 0.08. mg/cm2), high power densities (> 1.8 W/cm2) and high durability (> 6000 hours). How does one achieve higher power density with lower catalyst loadings?

MEA development

By using thinner layers in MEA components, shorter transport distances for protons, electrons and gases can be reduced. Thin membranes (< 10 µm) with lower crossover of gases will be prototyped in the project. Another concept vital to reducing catalyst loading is the application of X-Y-Z graded catalyst layers. Similarly, porosity and ionomer content can be optimised for performance. Ionomer distribution is especially important for optimal transport of liquid water away from the cathode.

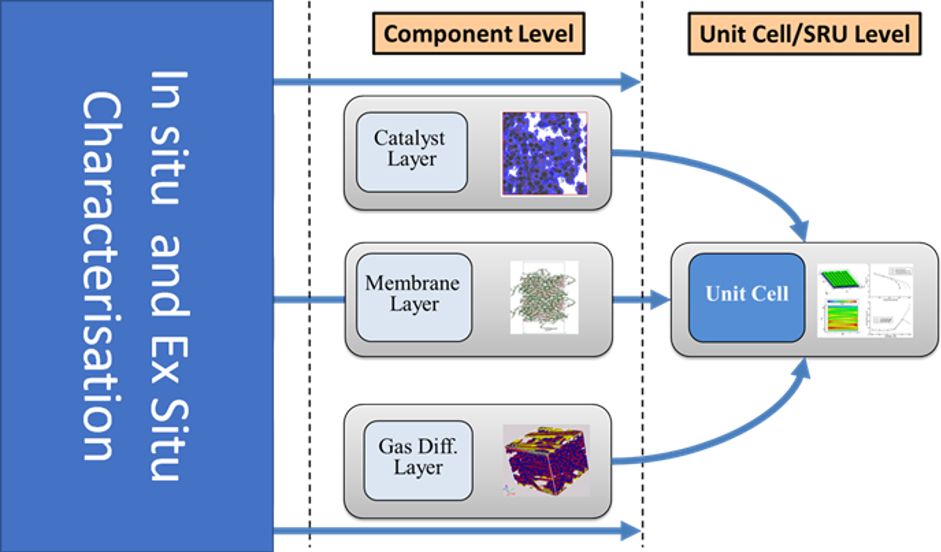

Characterisation of components

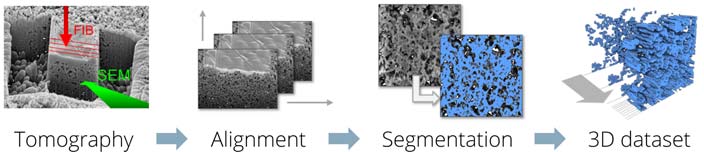

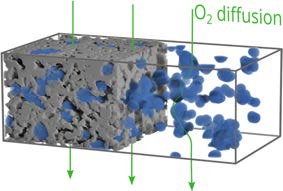

Characterisation of both state-of-art and beyond state-of-art components is essential for the understanding of their intrinsic performance. A wide range of ex-situ characterisation techniques will be applied. FIB-SEM tomography will be used for 3D reconstruction of the catalyst layers with a voxel size below 10 nm. IMTEK has developed a contrast enhancing method via atomic layer deposition of ZnO that has made the segmentation step less time consuming. The reconstruction of the catalyst layer structure then allows extraction of structural parameters and assessment of local gas diffusion and water transport inside the catalyst layer. In contrast to bulk methods such as BET or MIP, tomographic reconstruction allows differentiation between specific regions of the catalyst layer at different locations within the layer. This is key to investigating the ultrathin X‐Y‐Z catalyst layers envisioned in this project.

|

|

To quantify the effect of different transport processes on performance it is necessary to conduct in-situ testing of complete MEAs. The approach that will be taken in this project is based on a voltage loss breakdown strategy adapted from the US DOE FC-APOLLO project. Thus, a plethora of electrochemical characterisation techniques will be applied to the harmonised single cell hardware and to 'quasi-1D' hardware (i.e. with uniform gas concentration across the electrodes in the XY plane).

Modelling

CAMELOT will continue the development of the FAST-FC™ modelling framework that was developed as part of FC-APOLLO. FAST-FC™ is an open source modelling tool built using the OpenFOAM platform. It uses descriptions of fundamental physical processes along with material parameters to predict single repeat unit performance. This makes it possible to model the interaction between the physical processes that occur within a PEMFC and build an understanding of how to improve performance. Processes that underpin the observable performance and degradation at the unit cell level can be evaluated. The understanding of PEM fuel cells is continuously improving. An important task within CAMELOT is, therefore, to integrate state-of-art and beyond state-of-art material sets and to update the prevailing theories, so that next generation MEAs can be modelled accurately.

Concept and methodology

CAMELOT will start with the production of state-of-art MEAs using baseline materials already developed in other FCH JU funded projects (VOLUMETRIQ, GAIA) with a range of layer thicknesses, compositions, catalyst loading etc. These materials will be used to parameterise key MEA variables used by the FAST-FC™ model. These MEAs will then be characterised for various physico-chemical parameters (e.g. porosity, pore size distribution, thermal/electric/ionic conductivity) and tested for performance in 50 cm2 hardware and voltage loss breakdown analysis will be applied.

The FAST-FC™ models will be updated with a more robust and mechanistic liquid transport description for the MEA components and an improved description of water transport within the ionomeric materials. Characterisation parameters and model validation data will be derived from the characterisation work at test cell and single repeating unit (SRU) level. The improved model will be used to simulate a state-of-art MEA in order to extract a theoretical understanding of the performance limitations for the state-of-art materials.

From characterisation and modelling of state-of-art materials, the origin of the key performance limitations for the MEAs will be identified. Using this information, thin catalyst layer and membrane designs will be proposed and prototyped using techniques such as additive manufacturing to produce new beyond state-of-art MEAs. These MEAs will feature gradients in the X-Y-Z directions in the catalyst layer and ultra-thin membranes. Extensive in-situ performance and ex-situ characterisation will again be applied to quantify transport limitations of the beyond state-of-art MEAs. This experimental testing will be used to validate the FAST-FC™ model for beyond state-of-art MEAs.

The FAST-FC™ model will, following the validation for beyond state-of-art MEAs, be used to predict the performance of the beyond state-of-art MEAs in the automotive SRU hardware and predict the influence that the different theoretical materials and designs would have on performance. The model simulations will be used to provide an initial filter and recommendations for designs that address the performance limitation of the state-of-art materials in the automotive SRU Hardware.